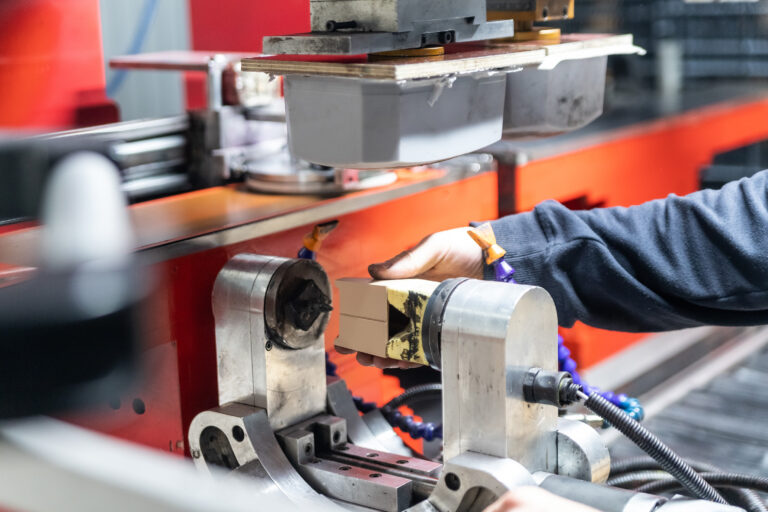

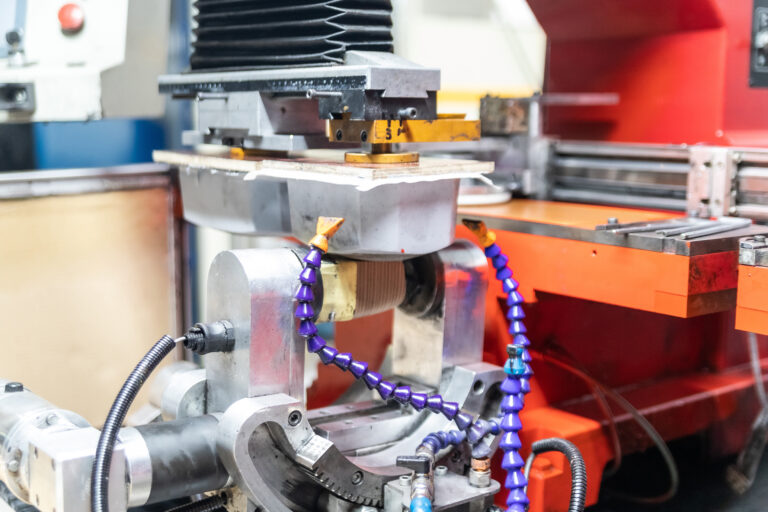

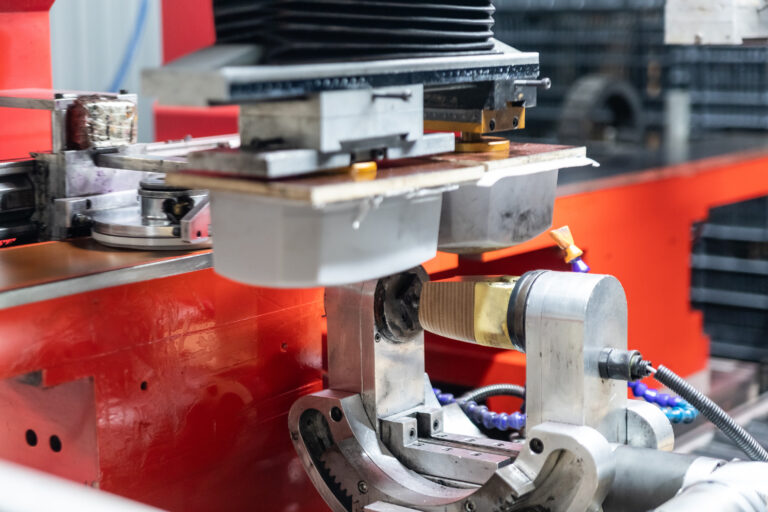

Production

Our heel factory is equipped with modern production machines, which, combined with experienced staff, guarantee the high quality that meets the needs of our customers.

Showroom

Our archive developed for over 40 years of the company’s history, which currently includes a wide range of over 2,500 heels, heel tips, wedges etc. This is the result of years of collaboration with our clients.

Determining the concept

From the design to the finished lasts, heel, and shoe. We canprovide the client with professional and comprehensive advice in the design of women’s footwear. We systematically develop and analyze individual collections for each fashion season, taking into consideration constantly changing fashion trends.

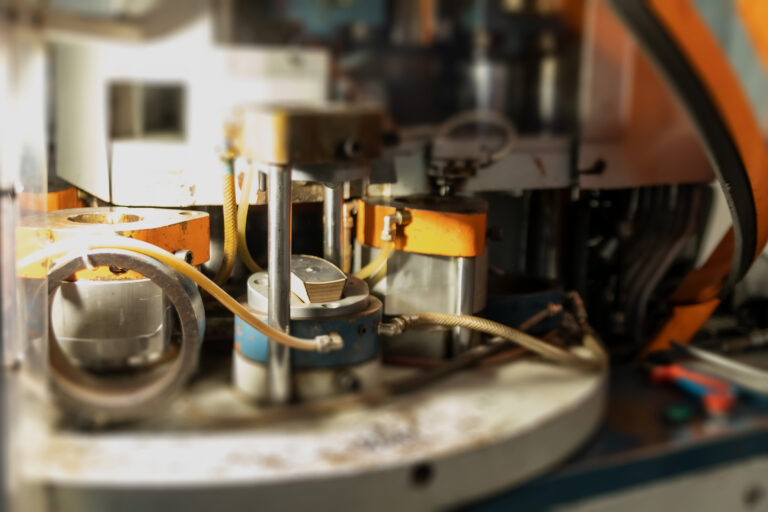

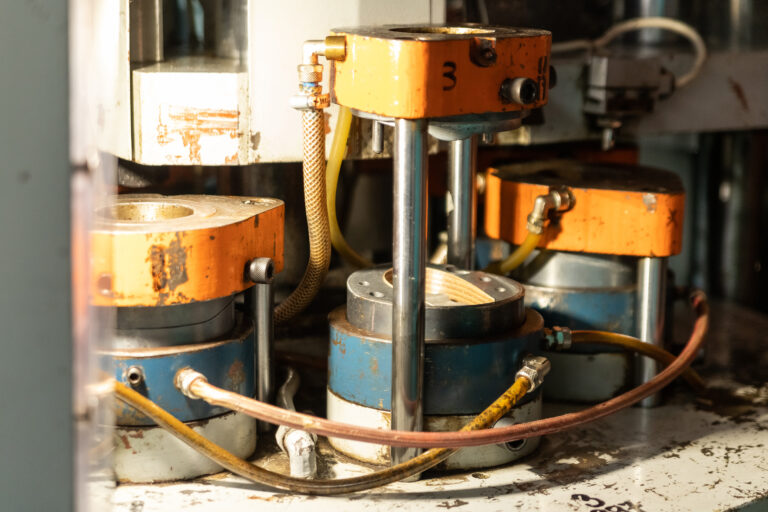

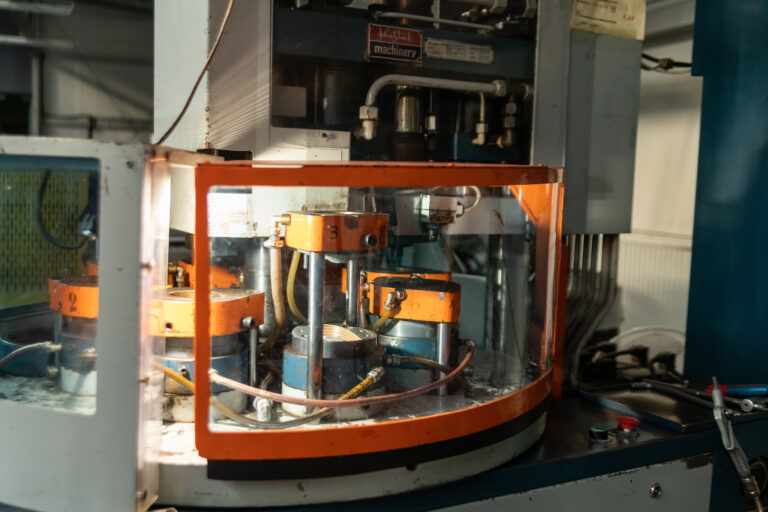

Pad printing

Pad printing is being used by us to decorate heels, wedges and some types of soles with finishes that can imitate leather, wood, cork and any other texture or custom design.

Pad printing is certainly a higher and more complicated level of finish than painting. We are equipped with three five-axis printing machines and the amenities for our own production of clichés and pads.

Paint shop

Today, more than ever, the quality of the finished product is extremely important. That is why we have our paint shop that is able to create various finishes. From traditional stripes for a leather effect to varnishing in all imaginable colours. From metallization to the effect of brushing, polishing, etc. In painting our products, we have combined the pursuit of high quality with great care for respect for the environment. That is why we decided to use certified paints and thinners with a negligible impact on the natural environment.

Natural cover

Our company also performs heels covered with natural leather. These are the highest quality products used for exclusive footwear. Real leather heels are made of plastic heels, whose outer surface is made of real skin strips.

These stripes are properly cut and handly inserted into the heel form. Then the material is injected into it. After making a series of various surface finishes, the heel spiced up this way becomes an element of high-quality footwear.

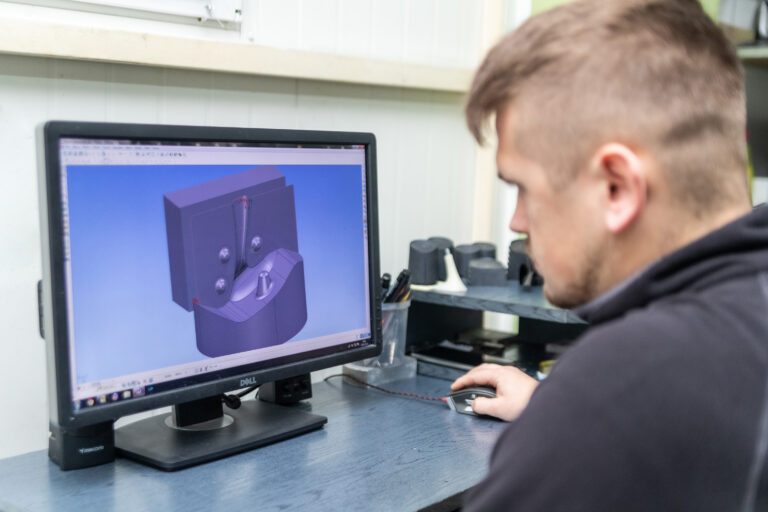

Heel design & Toolroom

It all starts with analyzing and listening. Your visions and needs are the most important for us. We start with a sketch, which in our case is a drawing in the latest CAD program, which we transform into a prototype, and then using a CNC machine or 3D printer into a model. From the model, we go to the mould, then to the series, and so on through quality control and only then to production. A team of professionals is fully dedicated to designing, modelling and producing injection moulds. The most modern machine park, the latest CAD/CAM programs and continuous technological investment allow us to make a model of a heel for a production last or a shoe in up to two hours.

Sustainability

The R-BUT company cares about the environment. For the production and finishing of our products, we use only original materials that meet the standards and certificates.

All possible waste generated in the production process is recycled, distilled or completely utilized by specialized companies.

In addition, our company is equipped with photovoltaic panels with a power of 50 kW, the energy from which is used directly for ourproduction.